Cones and warning lights

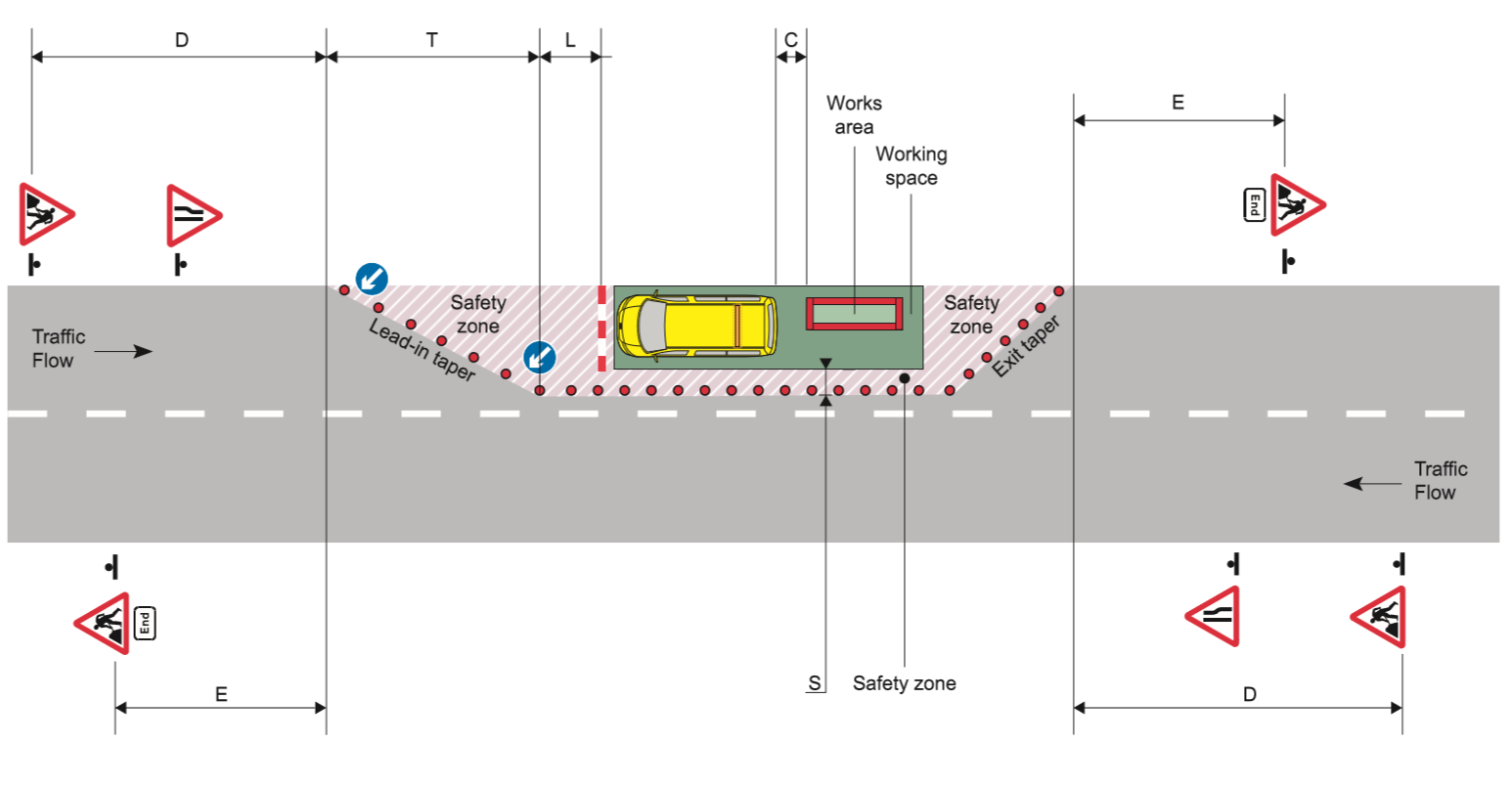

For the minimum size of cones and their placement in lead-in tapers, exit tapers, and safety zones, refer to the table inside the back cover. The retroreflective sleeves of cones must be kept clean. Damaged cones/sleeves must not be used.

All street and road works on roads with a speed limit of 40 mph or more must have warning lights (formerly known as road danger lamps) illuminated in poor visibility or during the hours of darkness. If your risk assessment requires it, warning lights should also be used on lower-speed roads. Steady warning lights can be used on all lit or unlit roads regardless of the speed limit. Where street lighting is present and illuminated, and where the speed limit is 40 mph or less, flashing warning lights are permitted as an alternative. See table in the Warning lights section of the Code.

Lead-in taper

The recommended lead-in taper is given in the table inside the back cover. Sometimes it might not be practicable to provide the full taper. If this happens on congested roads with speed limits of 30 mph or less, shorter lengths of taper may be used. Reduced tapers should always be as long as permitted under the circumstances. However, they must not be reduced to less than 45º unless there are restrictions associated with parked vehicles (see the Works on single carriageway roads section of this Code.)

Caution: Where reduced taper lengths are used, the siting distance (D) of the first sign in advance of the taper must be no less than 20 metres.

Traffic barrier

When a traffic lane is closed for fixed (i.e. not short duration or mobile) works to take place, a traffic barrier with a retroreflective red and white barrier sign should be placed across the lane as shown in the layout diagrams.

Site layout

You must include the works area, working space and safety zone in the area to be marked off with cones, and/or barriers. Warning lights should be placed where necessary (see the Warning lights section of this code). You must provide safety zones when either:

- operatives are present; or

- a pedestrian walkway is located in the carriageway.

Safety zone

The safety zone is provided to protect you from traffic and to protect the traffic from you.

When working in a footway, remember you must provide a safety zone in the carriageway if the working space is closer to the edge of the carriageway than the width of the sideways clearance (S). If cones are placed in the road, advance signing will be required.

These same principles apply when working in a verge or cycle track adjacent to the carriageway.

Notes

Notes

- For numbers and minimum size of cones, and dimensions D, T, C, L, S and E, see table in the Setting out site section of this Code.

- An information board (omitted here for clarity) must be displayed.

Warning: Do not enter the safety zone in the normal course of work. Materials, equipment and vehicles must not be placed in this zone. You should only enter the safety zone to maintain cones, barriers and other road signs.

The basic safety zone including a works vehicle, (see figure above) is made up of:

- a lead-in taper of cones whose length (T) generally varies with the speed limit and the width of the works (although a 45° lead-in taper is used for shuttle working and short duration stops);

- the longways clearance (L), which is the distance between the end of the lead-in taper and the first traffic barrier placed across the lane. L will vary with the speed limit;

- the sideways clearance (S), which is the width between the working space (or in some cases, the pedestrian walkway) and moving traffic; and

- the exit taper.

See inside the table in the Setting out site section of this Code for dimensions T, L, C and S.

Sideways clearance (S) depends on the speed limit in force, although you should consider as part of your risk assessment if a greater width than stated in the table would be appropriate, especially on roads with a high speed limit. If traffic consistently exceeds the speed limit, this should also be taken into consideration when reviewing the width of the safety zone. This may result in a restricted width available to traffic, and could cause particular problems for drivers of large vehicles at junctions and bends. If so, you might need to consider other traffic management options. See the Traffic control section of this code for information regarding unobstructed widths.

At times when no operatives or hazards within the site (e.g. open excavation, plant, materials or spoil heap) are present, and no pedestrian walkway is provided in the carriageway, the overall size of the layout can be temporarily reduced to make less of an obstruction to traffic . Dimensions of the longways clearance (L) and sideways clearance (S) can be reduced (or these spaces omitted altogether) and the length of taper (T) adjusted to match the reduced width. L, S and T must be restored to the appropriate dimensions when work restarts.

Where the coned off area is simply protecting a hazard, it may be possible to temporarily reduce the size of the working space. In this case however, dimensions L, S and T will still be required, even though no works are taking place.

Warning: Where the width of the usable carriageway does not permit the necessary sideways clearance to be maintained and a full road closure is not practicable, a safe method of work must be agreed before starting work. Such agreement must be between the works promoter and the appropriate highway authority.

Exit taper

An exit taper is normally required and should be at 45° to the kerb line or road edge. However, for works on a dual carriageway where a works vehicle exit is needed, the exit taper may be omitted as long as the end of the works is properly signed as a works vehicle exit.