Base preparation

- Bond coating materials are generally based on rapid curing anionic or cationic bitumen emulsions to BS 434, with approximately 40% bitumen content. New bond coating materials are becoming available and the trial use of more modern variants is recommended.

- Application rates in this Code are quoted in kg/m2 of residual bitumen. This differs from the previous Code which quoted rates in l/m2 of total emulsion. For example, the rate of 0.15 kg/m2 residual bitumen equates approximately to 0.35 l/m2 of 1-40 or 0.25 l/m2 of K1-60 emulsion.

- Further guidance on application of bond coats can be found in BS 594987.

Edge preparation

The shape of the trench should not hinder the compaction of material at the reinstatement perimeter. When angles less than 90° are used, special care must be taken to comply with compaction requirements. These include use of appropriately shaped hand compaction tools.

Edge sealant materials are generally based on rapid curing bitumen emulsions to BS EN 13808, typically in the range 40 to 100 pen and approximately 70% bitumen content, or hot bitumen to BS EN 12591 typically 50 or 70 penetration grade. An increasing number of high build and rubberised edge sealants are becoming available and, in general, are preferred. Alternatives to these materials exist and if there are any doubts as to their effectiveness they may be used on a trial basis (A9).

When using edge sealant materials, strict adherence to manufacturer’s instructions is essential. Depending on weather conditions, brushed sealant drying times may vary between 5 minutes and 2 hours, whilst spray sealant times may vary from 1 to 15 minutes before reinstatement can take place.

Additionally, before application:

- All excess water and loose material should be removed from the cut faces of the reinstatement;

- All bound vertical edges must be clean and free from slurry and dust etc. with the stone in the existing layers clearly visible.

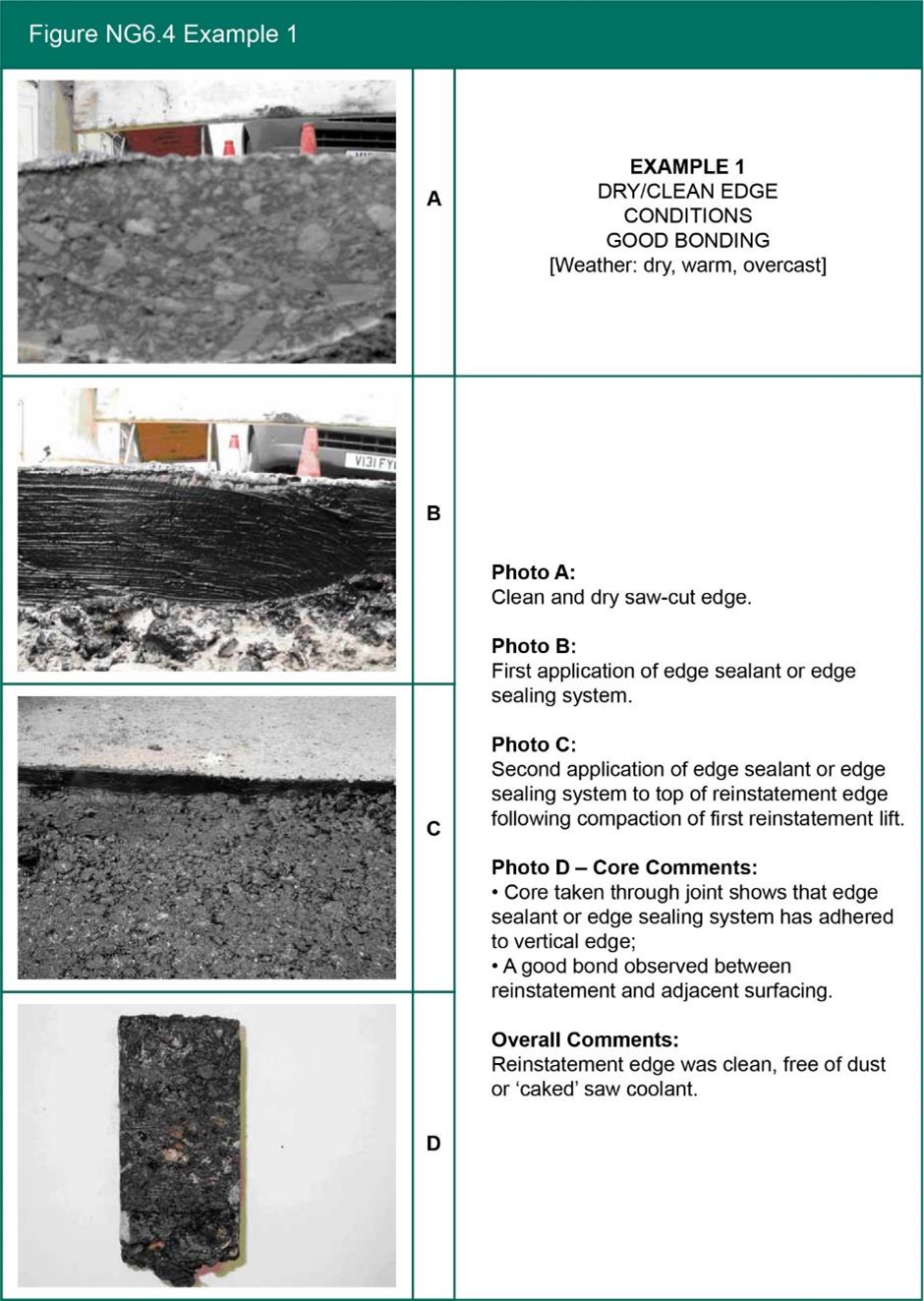

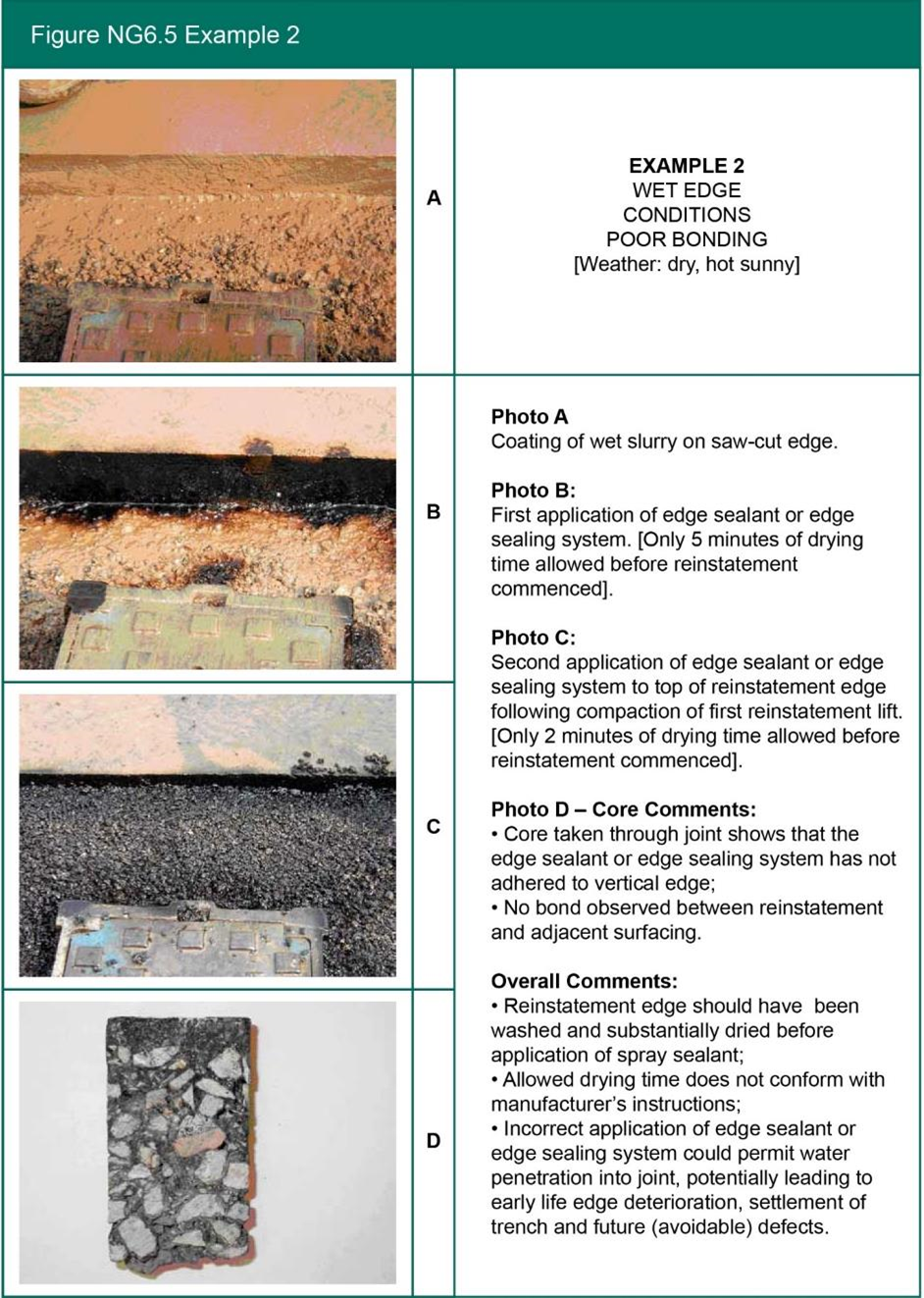

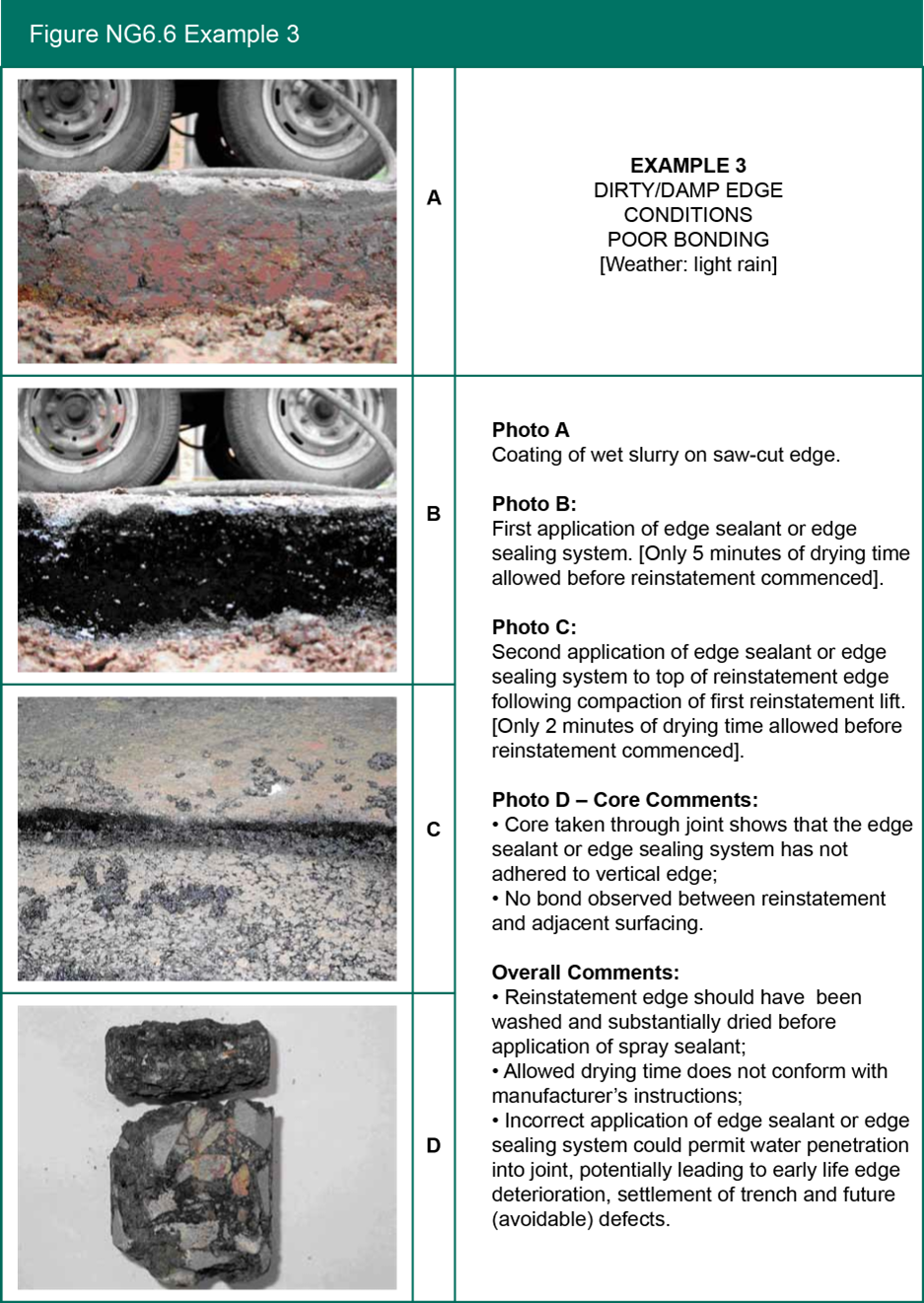

The following case study data sheets illustrate the results of edge sealant application under different edge conditions:

- Figure NG6.4: Example 1 – dry and clean;

- Figure NG6.5: Example 2 – wet;

- Figure NG6.6: Example 3 – dirty and damp.

Overbanding assists in preventing water ingress and seals the edge of a reinstatement at the surface. Skid resistance can be measured using the pendulum test. Overbanding can be detrimental if it creates localised ponding.

The following information is typically retained by the undertaker in relation to any potential future defects:

- Confirmation from the certificate holder that the installer is approved for installation of their proposed system.

- A copy of the Method Statement in line with the certificate for the chosen system.

- A copy of the material data sheets and/or company COSHH sheets.

- The results of all quality control checks carried out on site by the undertaker and quality assurance information compiled in accordance with the requirements of the Product Acceptance Scheme certificate, including results from surveillance visits must be made available on request.

The fact that a core may separate is not, on its own, evidence that no edge sealant has been used or of a lack of bond between layers. It may be due to damage during coring. Any investigation into bond should consider risk mitigation to avoid damage during the sampling and test preparation process.