- S6.6.4

- Slots must be cut to the width of the duct(s) to be accommodated plus a minimum of 2 mm.

- S6.6.5

- The minimum depth of excavation must be sufficient to enable reinstatement of the micro trench; including the minimum combined thickness of courses 1, 2 and 3 above the apparatus as specified in S6.6.16.

- S6.6.6

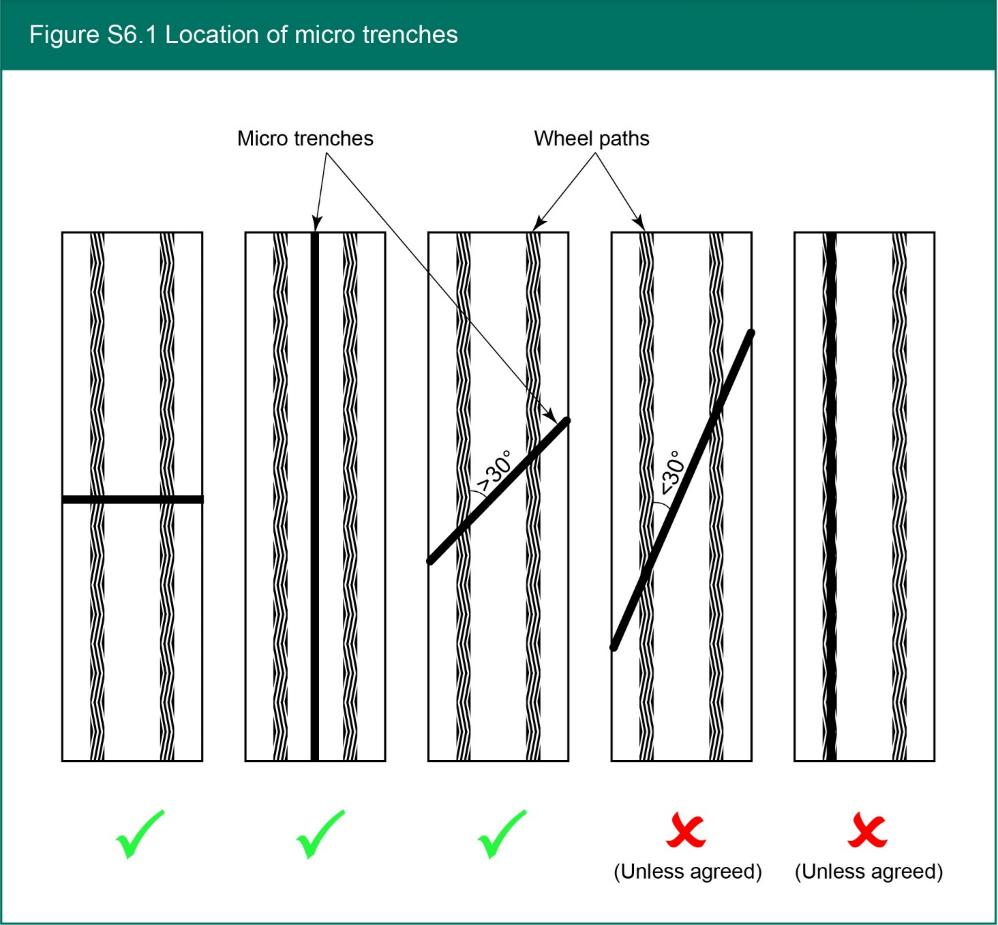

- The line of a micro trench must be carefully planned before any excavation takes place. Micro trenches must not be placed under a wheel track zone in the direction of travel as defined in Figure S6.1 without the agreement of the authority.

- S6.6.7

- After cutting to the required depth, the excavation must be cleaned to produce a clear and dry slot.

- S6.6.8

- Any large pieces of aggregate or agglomerations of aggregate protruding into the slot after the initial cleaning must be removed or hammered into the base of the slot so that it does not interfere with installation of the duct/cable. This can be done using a percussive tool with a narrow tip.

- S6.6.9

- Where cutting or clearing the micro trench causes damage (e.g. visible cracking) or significant vertical or lateral disruption to the surrounding surface, the excavation must be carried out as per S3 and must be reinstated in accordance with S6.2, S6.3 and S6.4 or S6.5, as appropriate. Significant vertical disruption is where the surface has been raised or depressed by more than 6 mm, in line with S2.2.1. It is not necessary to prescribe a limit for lateral disruption as the requirements of S6.8.6 will prevail. However, the frequency of lateral disruptions must be monitored to determine their significance.

Skip to main content